Titanium oxide is known as a Transition metal and is the 9th most abundant element in Earths’ crust, occurring mainly in igneous rocks. It has the chemical symbol Ti and is number 22 in the table of elements, having the atomic number 22 (the number of protons in the atomic nucleus).

Discovered in England toward the end of the 18th century by a pastor, it was originally given the name Manaccanite after his local parish. Later it was renamed Titanium by a German chemist after the Greek Titans.

As a metal it is extremely useful in the manufacturing of higher quality metal products. Titanium metal has a low density but a very high strength. It is described as somewhat inert, in that it doesn’t really interact or do anything that leads to breaking down in any way, and this is exactly why it is so useful as a structure metal. It resists acids and alkaline and does not corrode, a welcome relief from the annoying experience of rust or white powder aluminium oxide found in many steel and aluminium products.

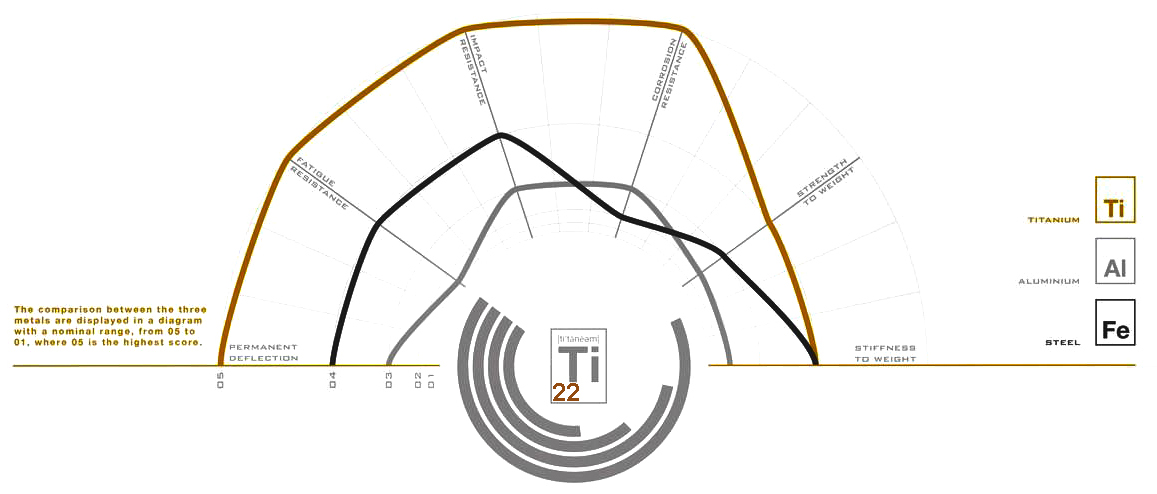

As a bicycle frame it is employed as an alloy. In the case of Van Nicholas frames, the alloy is 94% Titanium, 2.5% Vanadium and 3% Aluminium. This is why the description 3Al/2.5V Titanium appears on Van Nicholas frames. Its advantages to aluminium and steel can be seen in the illustration below.

As a finished product, Van Nicholas titanium frame bikes are like nothing else. They represent the pinnacle of bicycle design, both in terms of ride experience, toughness and longevity of frame material, and the aesthetically beautiful soft brushed finish simply adds to their desirability.

Below is what Van Nicholas say about Titanium and their bicycle frames.

‘TITANIUM PROPERTIES

Simply beautiful

The elegant lines of our frames accentuate the natural beauty of Titanium. The soft glow of lightly brushed and polished Titanium is unique. That’s why we choose not to paint our frames. It needs no embellishment; the timeless allure of naked Titanium is hard to resist, impossible to ignore.

Powerfully agile

A great ride lies in the perfect balance of lateral stiffness for power transfer, and vertical compliance to absorb feedback from the road surface. Titanium has an unparalleled strength-to-weight ratio which ensures rigidity, and just enough give to make you feel like you are floating on air.

Immutably though

Titanium won’t give up when you are depending on it. It boasts superior fatigue life and impact resistance, and a natural coating of Titanium Dioxide ensures that no matter how punishing the conditions, it will never succumb to rust, decay or corrosion.

MATERIAL COMPARISON

When trying to pick a material for a bike frame, there are many really important material considerations; weight, stiffness, strength, toughness, impact resistance, ride quality, corrosion. We’ll consider all of these issues in the context of choosing a bike.

Permanent deflection

Permanent deflection, or plastic deformation as it is also known, is much higher in Titanium than other materials and accounts for its fabled ‘spring’. This is why a Titanium ride is so much more comfortable than other frame building materials.

Fatigue resistance

The inherent flexibility and high tensile strength of Titanium allows the energy stresses of regular use to be effectively dissipated without degradation of the material, ensuring Titanium frames stay stronger for longer.

Impact resistance

The high tensile, or ultimate, strength and low elastic modulus of Titanium combine to create unparalleled impact resistance, meaning Titanium frames can soak up much harder punishment than frames built from other materials.

Corrosion resistance

Titanium’s natural coating of Titanium Dioxide prevents it from oxidising in the atmosphere, so it will never rust, unlike steel, and, unlike aluminium, it will not corrode when exposed to acidic or alkaline environments. So aesthetic and performance quality will never be compromised by the weather.

Strength to weight

The tensile strength to density ratio for Titanium outstrips every other frame building metal. Simply put, for the same weight frame, Titanium will be twice as strong as steel and three times as strong as aluminium.

Stiffness to weight

Rigidity is essential for efficient power transfer and Titanium’s stiffness to weight ratio is superior to all other metals. Titanium combines low weight for easy climbing, high rigidity for blistering performance in the sprint and the perfect balance of both to deliver Titanium’s legendary ride quality.

TITANIUM FACTS

3Al/2.5V

All our frames are made from aerospace grade 3Al/2.5V Titanium, which contains 3% aluminium and 2.5% vanadium. This offers the perfect balance of strength and plasticity for use in thin-walled bicycle tubing.

Titanium Use

The 3Al/2.5V Titanium alloy we use was developed for use in high pressure hydraulic lines and is found on virtually all new military and commercial airplanes. We are not alone in recognising Titanium’s unparalleled qualities. Marine, architectural, medical and petrochemical industries all regularly make use of Titanium components, and you can also find its magical properties gracing consumer goods like golf clubs and jewellery.

Type of Tubing

We use two types of tubing to make our frames: cold-worked, drawn, seamless tubing and seamless hydroformed butted. Both types of tubing create extremely strong, lightweight frames, but the seamless hydroformed butted tubing is even lighter and more durable.

Environmentally Friendly

Once produced, Titanium is an environmentally friendly metal. All of the scrap we generate through the manufacturing process can be fully recycled.

Strength

Titanium, named after the Titans of Greek mythology, famed for their legendary strength, is twice as strong as aluminium and half the weight of steel.

Tolerance

Titanium has an incredibly high tolerance and will maintain the same properties up to 600°C.

Production Process

Titanium’s extreme oxygen reactivity (the same process that makes it so impervious to corrosion) makes production of the seamless tubes a very long and expensive process – hence the premium price tag’.

.….and finally

© Pedal Barn 2017